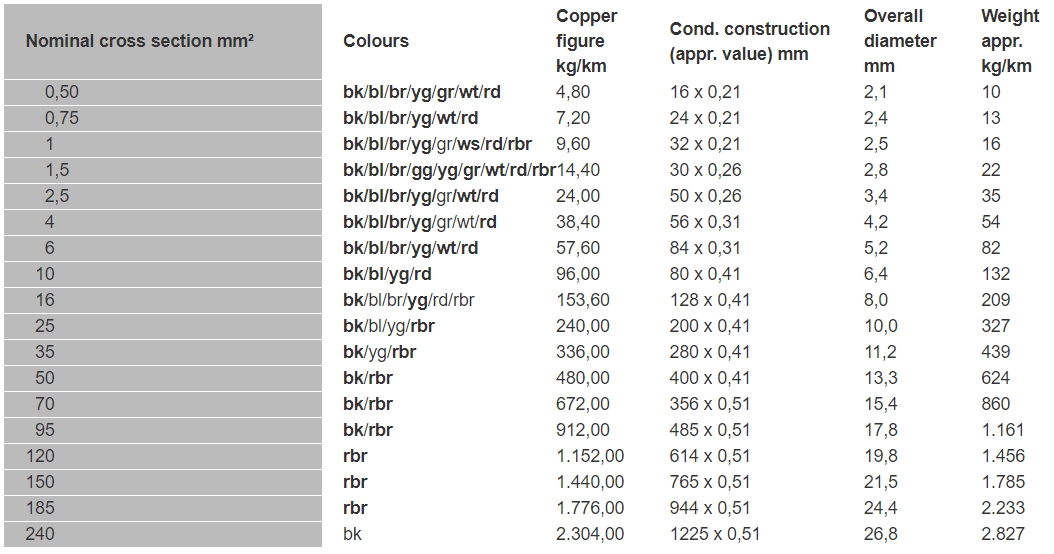

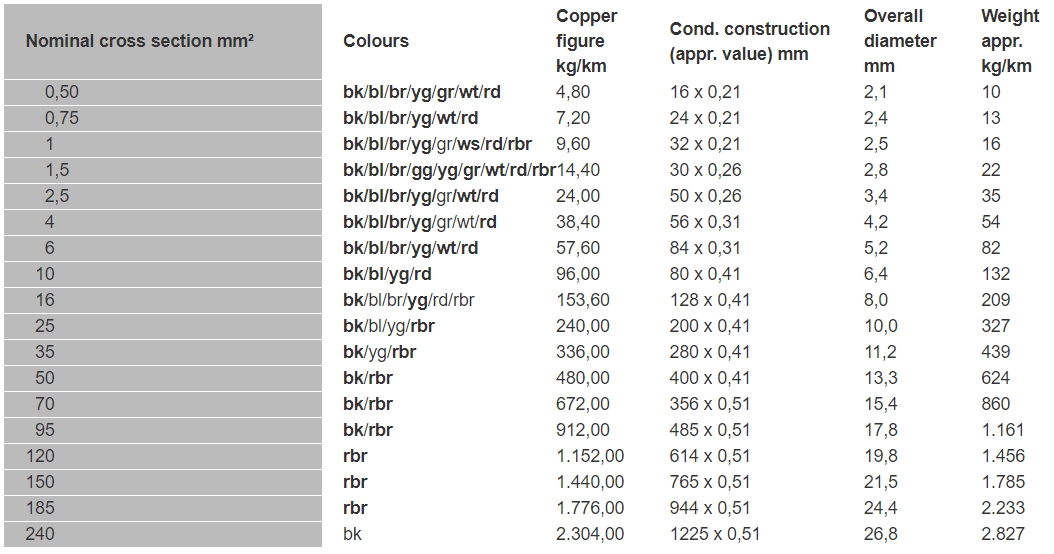

Tinned copper wire flex Halogen-free silicone rubber one core high temperature lead wire SiF SiFF are essential in applications where electrical components are exposed to extreme heat. These cables are designed to endure high temperatures while maintaining their conductivity and insulation integrity. This article provides a detailed overview of SiF and SiFF high-temperature wires, discussing their structure, features, uses, and a comparative analysis of their designs.

Structure of High Temperature Wires: SiF and SiFF

SiF Wire:

-

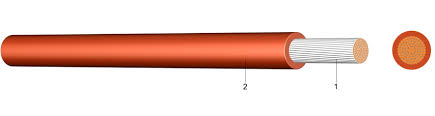

Conductor: SiF wire typically uses finely stranded tinned copper or nickel-plated copper, known for its high-temperature resistance and excellent electrical properties.

-

Insulation: The insulation is made from silicone rubber, which stands out for its flexibility and thermal stability. Silicone can withstand continuous exposure to temperatures up to 180°C and intermittent exposure up to 200°C.

-

Sheath: SiF wires usually do not have an outer sheath; the silicone insulation directly covers the conductor.

SiFF Wire:

-

Conductor: Similar to SiF, SiFF also uses tinned or nickel-plated copper conductors. However, the stranding in SiFF is typically more fine as class 6,enhancing its flexibility.

-

Insulation: SiFF also employs silicone rubber insulation. The key difference is often in the grade or formulation of the silicone used, which may provide slightly better flexibility or different environmental resistance characteristics.

-

Sheath: Like SiF, SiFF generally does not include a separate sheath beyond the silicone insulation.

Features of Tinned copper wire flex Halogen-free silicone rubber one core high temperature wire SiF SiFF

-

High-Temperature Resistance: Both wires are capable of handling up to 180°C continuously, making them suitable for high-heat environments.

-

Durability: Silicone insulation provides excellent resistance against aging, weathering, ozone, and varying temperatures.

-

Flexibility: Particularly in SiFF wires, the finer stranding of the conductors makes them highly flexible, suitable for installations requiring tight bending radii.

-

Chemical Resistance: Silicone is resistant to a variety of chemicals, including some acids and alkalis, making these wires robust in corrosive environments.

Applications of SiF and SiFF Wires

SiF and SiFF wires are widely used across various high-demand industries:

-

Automotive: In engine compartments where high temperatures can quickly degrade less robust wiring.

-

Industrial Machinery: In manufacturing equipment and ovens where operations involve high temperatures.

-

Aerospace: In aircraft systems where reliability and resistance to extreme conditions are crucial.

-

Household Appliances: In items like ovens, toasters, and coffee machines where electrical wiring is exposed to high temperatures.

Comparison of SiF and SiFF Wires

While SiF and SiFF wires share many similarities, including their high-temperature capabilities and chemical resistance, there are subtle differences that may make one more suitable than the other depending on the application:

-

Flexibility: SiFF wires are generally more flexible due to their finer conductor stranding. This makes SiFF a better choice for applications where cables are frequently bent or twisted.

-

Tags:

silicone rubber wire