Welding machines demand cabling solutions that can withstand extreme conditions, including high temperatures and mechanical stress, without compromising performance. Welding machine wire anti-freeze and high temperature resistance welding wire 16 25 35mm2 special cable soft wire ground wire offer an advanced solution, contrasting significantly with standard grounding wires. This article provides an in-depth look at the structure, features, applications of these specialized welding cables, and compares them to ordinary grounding wires, serving as a comprehensive guide for professionals seeking reliable and durable cabling for welding operations.

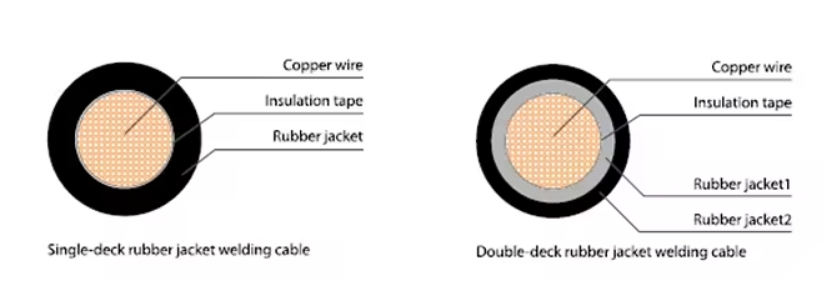

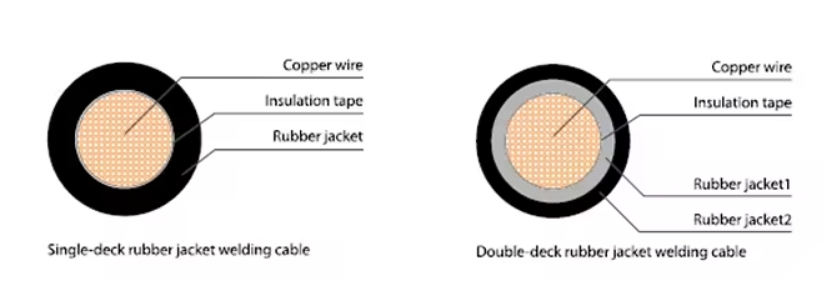

Structure of Specialized Welding Cables

Specialized welding cables are meticulously engineered to meet the rigorous demands of welding applications:

-

Conductor: Made from finely stranded copper, offering excellent electrical conductivity and flexibility, essential for the dynamic movements in welding operations.

-

Insulation: A key differentiator, the insulation is composed of a high-grade, flame-retardant rubber or synthetic compound, designed to resist high temperatures, sparks, and occasional flame contact.

-

Outer Jacket: The outer sheath is typically made from a robust, flexible, and heat-resistant material like neoprene or EPDM, providing additional protection against physical abrasions, moisture, and extreme temperatures.

Key Features of Welding machine wire anti-freeze and high temperature resistance welding wire 16 25 35mm2 special cable soft wire ground wire

-

High-Temperature Resistance: These cables are capable of withstanding temperatures significantly higher than standard cables, making them ideal for the intense heat generated during welding.

-

Flexibility: Despite their durability and resistance to harsh conditions, these cables retain exceptional flexibility, facilitating easy handling and manipulation by welders.

-

Durability: Engineered for resilience, the cables exhibit high resistance to cuts, tears, abrasion, and various chemicals, ensuring a long service life in rugged environments.

-

Enhanced Safety: The flame-retardant insulation and jacket materials contribute to safer welding operations, reducing the risk of fire and electrical hazards.

Applications of Welding machine wire anti-freeze and high temperature resistance welding wire 16 25 35mm2 special cable soft wire ground wire

These specialized cables are indispensable in settings that require welding equipment, including:

-

Industrial Manufacturing: For assembly lines and workshops where welding is a critical part of the manufacturing process.

-

Construction and Infrastructure: In the construction of buildings, bridges, and other structures where on-site welding is necessary.

-

Automotive Repair and Fabrication: For welding tasks in auto repair shops and in the fabrication of custom vehicles.

-

Shipbuilding and Repair: Where durable and reliable welding connections are essential for the construction and maintenance of vessels.

Comparison with Standard Grounding Wires

While standard grounding wires play a crucial role in ensuring electrical safety, specialized welding cables offer several distinct advantages for welding applications:

-

Heat Resistance: Unlike standard grounding wires, specialized welding cables are designed to withstand the high temperatures associated with welding, preventing degradation and maintaining performance.

-

Flexibility and Durability: Welding cables are more flexible and durable than standard grounding wires, designed to resist the mechanical stresses and environmental factors encountered in welding tasks.

-

Safety Features: With flame-retardant properties and enhanced electrical insulation, specialized welding cables offer improved safety over standard grounding wires, particularly in the high-risk environment of welding.

Welding machine wire anti-freeze and high temperature resistance welding wire 16 25 35mm2 special cable soft wire ground wire with their robust construction, superior heat resistance, and enhanced safety features, are specifically designed to meet the challenges of welding applications. Offering significant advantages over standard grounding wires, these cables ensure reliable performance, flexibility, and safety in the demanding conditions of welding operations. For professionals in industrial manufacturing, construction, automotive repair, and other sectors where welding is essential, selecting the right welding cable is crucial for efficient and safe operation. This guide underscores the importance of choosing cables tailored to the specific requirements of welding tasks, highlighting the advanced materials and engineering that go into the development of specialized welding cables for optimal performance and durability.