RE-Y(ST)YRY IS UV Instrument cable are mainly used to connect and transmit power or signals to instruments, equipment or control systems. They are often used in automation, measurement, control and monitoring systems to ensure stable and reliable signal transmission. Instrument cables have the characteristics of anti-interference, high temperature resistance and corrosion resistance, and are suitable for equipment connection, signal transmission and data acquisition in industries such as petroleum, chemical, electric power and steel. Their high-quality electrical performance and mechanical strength ensure normal operation in harsh environments.

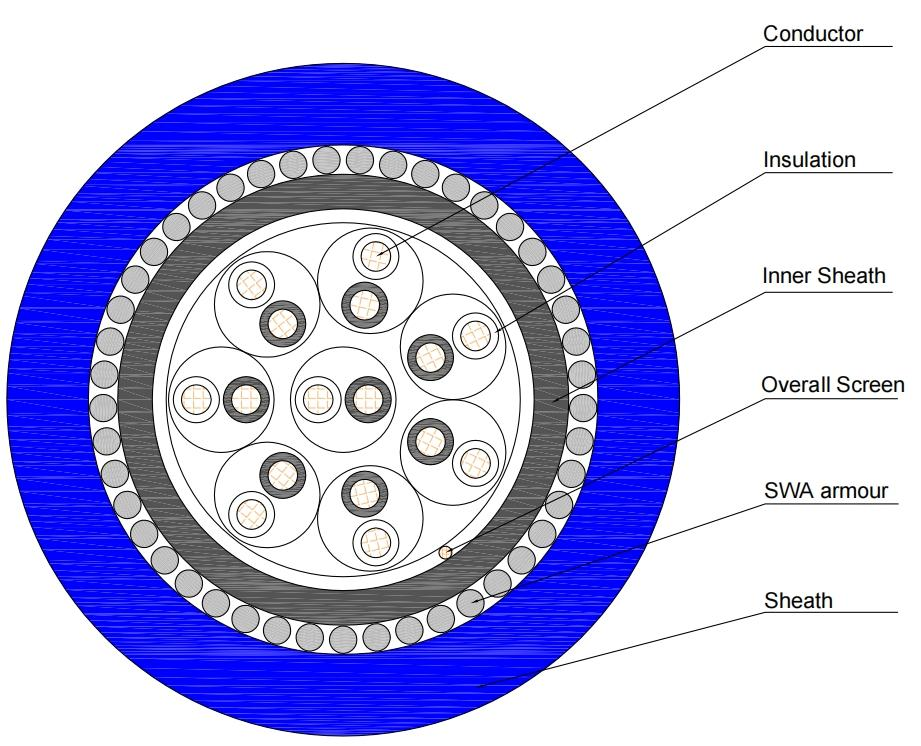

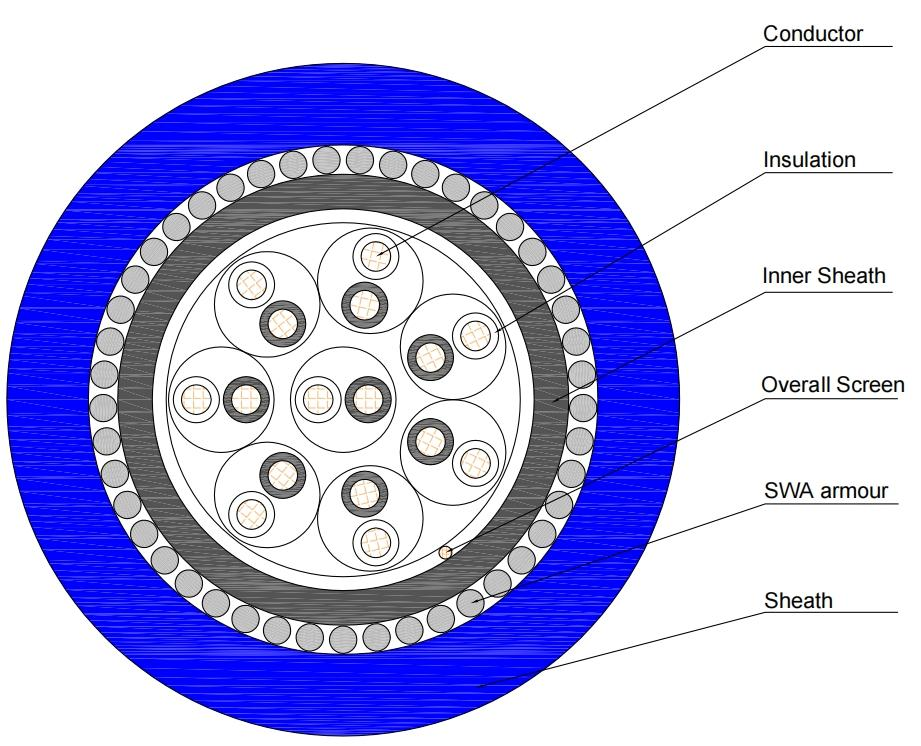

RE-Y(ST)YRY IS UV Instrument cable Structure

1,CONDUCTOR:Stranded plain annealed copper wire acc. to IEC 60228, Class 2 with no burrs, discoloration, oxidation and other quality defects on the surface.

2,INSULATION: Extruded V-90HT insulation material, insulation color: black, white, printed with digital code to distinguish; the average thickness of the

insulation should not be less than the nominal thickness specified in the table below, the insulation concentricity >75% (minimum

thickness/maximum thickness x 100% ), all insulated wire cores should withstand the 4kV spark voltage test without breakdown..

3,TWISTED: The insulated wire cores are twisted into pair, and after twisting, they are wrapped tightly with coded polyester tape, and the overlap rate is not less

than 20%. The coded polyester tape should be consistent with the number on the insulated core, and the twisted pitch should be 90~100mm.

4. CABLING:The pairs of wires are patterned into cables, and the cable forming direction is: right. The pitch is 18~20 times the outer diameter of the cable. The

cable core gap is filled and rounded with polypropylene tear film; the outside of the cable core is wrapped tightly with polyester tape.

5,OVERALL SCREEN: It is wrapped with copper-plastic composite tape with a thickness of not less than 0.05mm, with the metal side facing inward, the overlap

rate is not less than 20%, and a 7/0.30 bundle of twisted tinned copper wire is built-in.

6,INNER SHEATH:V-90HT inner sheath.the average thickness of the insulation should not be less than the nominal thickness specified in the table below.

7,ARMOUR: Use galvanized steel wire to evenly wrap around the inner sheath, with the total gap not larger than the diameter of one steel wire. After armoring,

use non-woven fabric to wrap tightly.

8,SHEATH:Use flame retardant V-90HT sheath material,Color Blue as client require. The average thickness of the sheath should comply with the process

requirements in the table below.