6 kV 10kv 30 kV MV Single Core EPR Rubber Ultra-Bendable NTMCWOEU cable is specifically engineered for medium voltage applications that demand high flexibility and exceptional electrical integrity. This cable is ideal for environments where both mechanical stresses and high electrical performance are critical. This article will explore the structure, characteristics, applications of the NTMCWOEU cable and provide a comparative analysis with the NSGAFÖU cable, focusing on their use in industrial and mining environments.

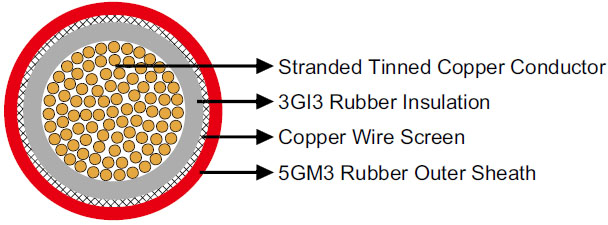

Conductor: The core of the NTMCWOEU cable features a finely stranded tinned copper conductor, known for its excellent conductivity and corrosion resistance. Surrounding the conductor is a semi-conductive layer that helps in maintaining uniform electrical fields and reducing electrical stress.

Insulation: The insulation is composed of Ethylene Propylene Rubber (EPR) coupled with a semi-conductive insulation layer. EPR provides superior dielectric strength and heat resistance, while the semi-conductive layer enhances the insulation's performance by mitigating surface discharges and electrical stresses.

Sheathing: The outer sheath is made from a robust, UV-resistant rubber compound that protects the cable from abrasion, moisture, and chemical exposure. This sheathing ensures the cable's durability in harsh environmental conditions.

While both NTMCWOEU and NSGAFÖU cables are known for their flexibility and robust construction, there are distinct differences that set them apart:

6 kV 10kv 30 kV MV Single Core EPR Rubber Ultra-Bendable NTMCWOEU cable is an excellent choice for demanding industrial applications that require cables to withstand high voltages and extreme bending conditions. Compared to NSGAFÖU cables, NTMCWOEU offers improved performance in high voltage environments and better handling of electrical stresses due to its advanced insulation design. Selecting the right cable depends on the specific requirements of the application, including voltage needs, environmental conditions, and mechanical stress factors. Understanding these unique characteristics ensures optimal performance and safety in industrial, marine, and renewable energy sectors.

Name: Lucky Li

Mobile:+86-18019826300

Tel:+86-0550-7788337

Whatsapp:+86-18019826300

Email:sales@chinajingzhou.com

Add:Jingsan Road, Xicheng District, Tianchang City, Anhui Province,China