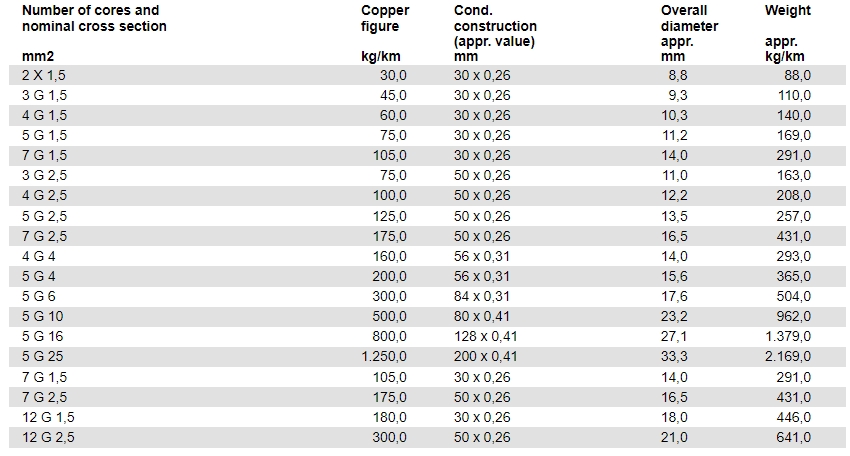

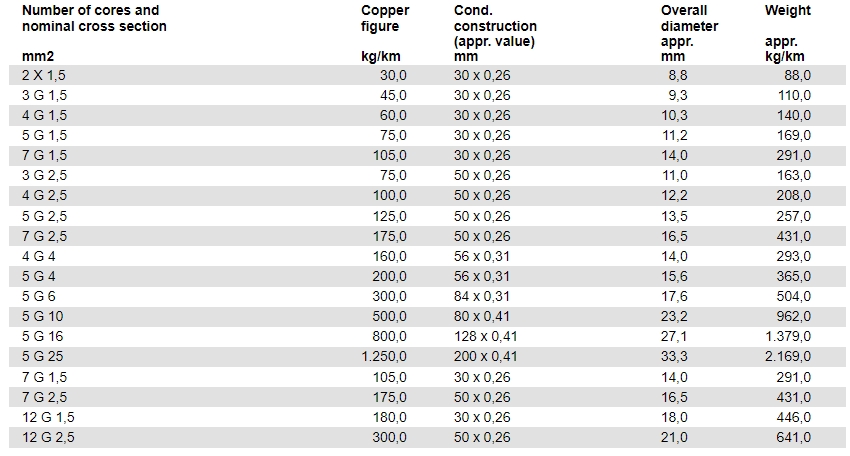

Wear-resistant and bend-resistant flexible polyurethane cable H05BQ-F H07BQ-F specifically the H05BQ-F and H07BQ-F, are renowned for their durability and flexibility. These cables are designed to withstand harsh environments and frequent bending, making them ideal for a variety of demanding applications.

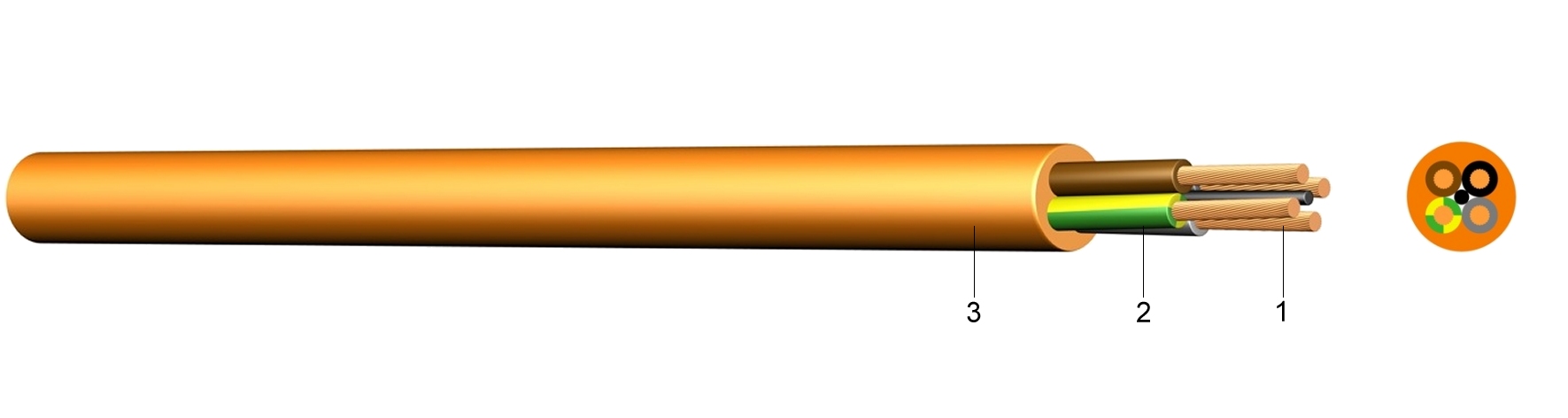

Structure of H05BQ-F and H07BQ-F Cables

Conductor:

-

Both H05BQ-F and H07BQ-F cables utilize finely stranded bare copper conductors, ensuring excellent electrical conductivity and flexibility. This allows for continuous power transmission even in applications requiring frequent movement.

Insulation:

-

The insulation in both cable types is made from polyurethane (PUR). PUR is selected for its exceptional properties including resistance to abrasion, oil, and various chemicals, as well as its flexibility at different temperatures.

Sheathing:

-

The sheath of both H05BQ-F and H07BQ-F cables is also made of polyurethane, enhancing their durability and wear resistance. This dual layer of PUR provides comprehensive protection against environmental factors.

Features of H05BQ-F and H07BQ-F Cables

-

Durability: Both cables are highly durable, resistant to wear and tear even under tough conditions.

-

Flexibility: Despite their toughness, these cables remain highly flexible, suitable for dynamic environments where cables are frequently moved or bent.

-

Resistance to Chemicals and Oils: Polyurethane provides excellent resistance to oils, greases, and a variety of chemicals, making these cables suitable for industrial applications.

-

Weather Resistance: Both types of cables perform well in diverse climatic conditions, from cold to hot environments, maintaining flexibility and structural integrity.

-

Fire Resistance: PUR cables are self-extinguishing and flame retardant, adding an extra layer of safety in potential fire scenarios.

Applications of H05BQ-F and H07BQ-F Cables

-

Industrial Automation: Both cables are extensively used in automated manufacturing processes where machinery frequently moves or rotates.

-

Outdoor Events: Ideal for powering lighting and sound equipment in outdoor settings due to their resistance to weather and mechanical stress.

-

Construction Sites: Both cables can be used on construction sites where cables might be subject to rough handling and exposure to building materials.

-

Portable Tools and Machinery: Suitable for power tools and mobile machinery that require a reliable power connection that can withstand frequent bending and wear.

Comparison Between H05BQ-F and H07BQ-F

While both cables share many features, there are key distinctions:

-

Voltage Ratings: H07BQ-F cables are generally designed for higher voltage applications compared to H05BQ-F. H07BQ-F can handle voltages up to 750V, while H05BQ-F is typically rated for up to 500V.

-

Cable Diameter and Weight: H07BQ-F cables are thicker and heavier, designed to handle more intensive mechanical stresses compared to H05BQ-F.

-

Suitability for Extreme Conditions: H07BQ-F is more robust, making it more suited for heavy-duty applications where cables might be exposed to higher risks of abrasion and mechanical damage.

Choosing between H05BQ-F and H07BQ-F cables depends on specific application needs, including the required voltage, environmental conditions, and mechanical stress levels. Both cables offer exceptional durability and flexibility, but the H07BQ-F is preferable for more demanding industrial applications due to its higher voltage capacity and enhanced mechanical robustness. These cables ensure that regardless of the demands of the environment, continuity of service and safety are maintained,another similar cable,H05RR-F H05RN-F Rubber flexible cable.