CU/PVC/OS/PVC 600/1000V Control Cable is a cable specially used in the control system. It can transmit control signals and power signals, and can also ensure the stability and reliability of signal transmission. The production standards of control cables are very strict, mainly including conductor materials, insulation materials and sheath materials. Its structure includes conductor, insulation layer and sheath. Control cables have technical characteristics such as anti-interference performance, chemical corrosion resistance and mechanical strength. In the field of industrial automation, control cables are widely used in various control systems, such as robot control, automatic production line control, etc.

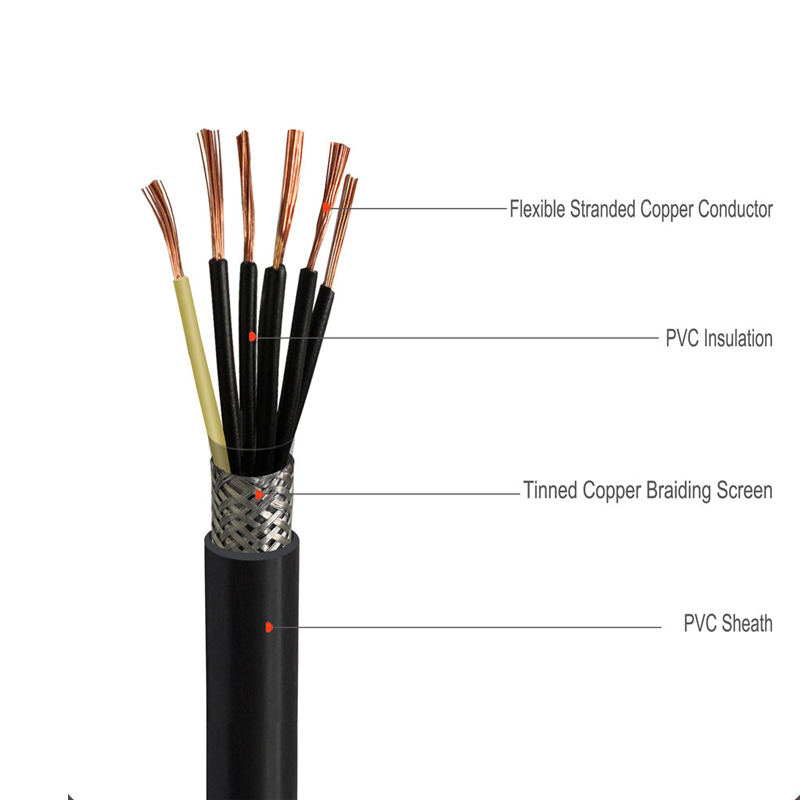

The structure of the control cable mainly includes a conductor, an insulation layer and a sheath. The conductor is the core part of the control cable, and its material is usually copper or aluminum. The insulating layer is an important part of the protective conductor, and its material is usually polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), etc. The sheath is an important part of the protective insulation layer, and its material is usually polyvinyl chloride (PVC), polyurethane (PU), etc. The structure of the control cable is relatively simple, usually only the conductor, insulation layer and sheath.

Common control cable models are KVV, KVVP, KYJV, KYJVP, etc. Among them, the KVV type control cable is a copper core PVC insulated PVC sheathed control cable, suitable for control, monitoring, signal transmission and other occasions with AC rated voltage of 450/750V and below. KVVP control cable is a copper core PVC insulated armored PVC sheathed control cable, suitable for control, monitoring, signal transmission and other occasions with AC rated voltage 450/750V and below. KYJV control cable is a copper core XLPE insulated PVC sheathed control cable, suitable for control, monitoring, signal transmission and other occasions with AC rated voltage 1kV and below. KYJVP control cable is a copper core XLPE insulated armored PVC sheathed control cable, suitable for control, monitoring, signal transmission and other occasions with AC rated voltage 1kV and below.

The use of control cables is very wide, mainly used in various control systems, such as robot control, automatic production line control, power system control, etc. In addition, control cables can also be used as a replacement for power cables to improve the efficiency and stability of power transmission.

Compared with 300/500V instrument cables, the main difference of control cables is the purpose and structure. Control cables are mainly used in control systems, and their structure is relatively simple, usually only conductors, insulation layers and sheaths. The 300/500V instrument cable is used in instrumentation and control systems, and its structure is relatively complex, usually including conductors, insulation layers, shielding layers and sheaths. In addition, control cables need to transmit power signals, so the materials and thickness of their conductors and insulation layers also vary.

The control cable is a cable specially used in the control system, and its production standard refers to the IEC60052 standard of the International Electrotechnical Commission (IEC). The IEC60052 standard specifies common technical requirements for control cables, including insulation resistance, test voltage, and cable structure.

Insulation resistance is one of the important technical indicators of control cables, and its requirements are specified in the IEC60052 standard. According to the standard, the insulation resistance of the control cable should meet the following requirements: at 20°C, the insulation resistance between the conductor and the conductor should not be less than 100MΩ·km, and the insulation resistance between the conductor and the sheath should not be less than 50MΩ·km. These requirements can ensure that the control cable has good insulation performance during use, thereby ensuring the stability and reliability of signal transmission.

The test voltage is another important technical indicator of the control cable, and its requirements are also specified in the IEC60052 standard. According to the standard, the test voltage of the control cable should meet the following requirements: under the AC electric field, the test voltage of the control cable should not be less than 2.5kV, and the test time should not be less than 5 minutes. These requirements can ensure that the control cable has good voltage resistance performance during use, thereby ensuring the stability and reliability of signal transmission.

CU/PVC/OS/PVC 600/1000V Control Cable is an important cable product, which has broad application prospects in the field of industrial automation. Through strict production standard requirements and excellent technical characteristics, the control cable can ensure the accuracy and stability of signal transmission, thereby improving the operating efficiency and production efficiency of the equipment.

Name: Lucky Li

Mobile:+86-18019826300

Tel:+86-0550-7788337

Whatsapp:+86-18019826300

Email:sales@chinajingzhou.com

Add:Jingsan Road, Xicheng District, Tianchang City, Anhui Province,China