K type Thermocouple cable KX/PVC/OSC/PVC is a cable specially used in the thermocouple measurement system, and its function is to compensate the potential change caused by the temperature change in the thermocouple measurement. This article will elaborate on the introduction of thermocouple compensation cables, production standard requirements, structure, technical characteristics, uses, and the difference between compensation cables and instrument cables.

1. Introduction of thermocouple compensation cable

The thermocouple compensation cable is a cable specially used in the thermocouple measurement system, and its function is to compensate the potential change caused by the temperature change in the thermocouple measurement. Thermocouple compensating cables typically consist of two wires of dissimilar metals at the junction of which form a thermocouple. When the temperature of the thermocouple changes, a potential change will be generated, and this potential change can be transmitted to the instrument end through the thermocouple compensation cable, thereby realizing temperature measurement.

2. Production standard requirements

The production standards of thermocouple compensation cables mainly refer to the IEC584 standard of the International Electrotechnical Commission (IEC) and the MC96.1 standard of the American National Standards Institute (ANSI). These standards stipulate the technical requirements, structural requirements, test methods and other aspects of thermocouple compensation cables.

According to the IEC584 standard, the technical requirements for thermocouple compensation cables include: conductor material, insulating material, sheath material, resistance, capacitance, insulation resistance, test voltage, etc. Among them, the conductor material is usually copper or nickel-chromium alloy, the insulating material is usually polyvinyl chloride (PVC), polytetrafluoroethylene (PTFE), etc., and the sheath material is usually polyvinyl chloride (PVC), polyurethane (PU), etc. The structure of the thermocouple compensation cable is usually a double-layer insulation structure, that is, the inner layer is the thermocouple wire, and the outer layer is the compensation wire.

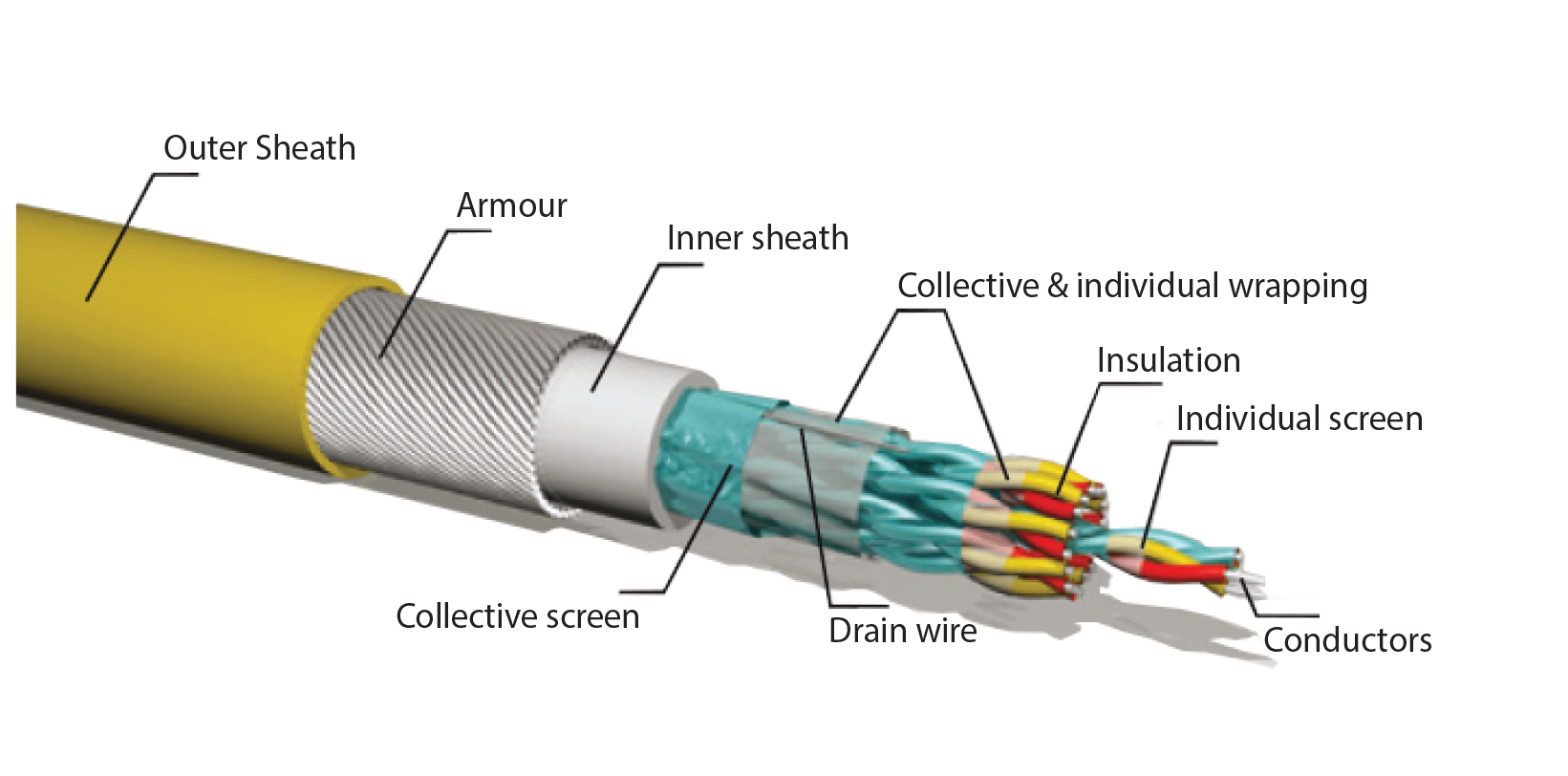

3. K type Thermocouple cable KX/PVC/OSC/PVC Structure

The structure of the thermocouple compensation cable is usually a double-layer insulation structure, that is, the inner layer is the thermocouple wire, and the outer layer is the compensation wire. Thermocouple wire usually consists of two wires of dissimilar metals at the junction that form a thermocouple. The compensation wire is usually made of the same material as the thermocouple wire, but its length and cross-sectional area are larger than that of the thermocouple wire to ensure that it can effectively compensate for the potential change caused by the temperature change in the thermocouple measurement.

4. K type Thermocouple cable KX/PVC/OSC/PVC Technical characteristics

The technical characteristics of thermocouple compensation cables mainly include resistance, capacitance, insulation resistance, test voltage, etc. According to the IEC584 standard, the resistance of the thermocouple compensation cable should meet the following requirements: the resistance of the thermocouple wire should not be greater than 10Ω/km, and the resistance of the compensation wire should not be greater than 5Ω/km. The capacitance of the thermocouple compensation cable should not be greater than 100pF/m, and the insulation resistance should not be less than 100MΩ·km. The test voltage should not be less than 2.5kV, and the test time should not be less than 5 minutes.

the table of different types of thermocouple compensating wire alloy materials, insulation colors, and temperature error ranges according to IEC60583 standard:

|

Thermocouple Type |

Alloy Material |

Insulation Color |

Temperature Error Range |

|

K |

NiCr-NiAl |

Green |

±1.5℃ or ±0.25% |

|

E |

NiCr-CuNi |

Purple |

±1.7℃ or ±0.25% |

|

J |

Fe-CuNi |

White |

±2.2℃ or ±0.75% |

|

T |

Cu-CuNi |

Brown |

±1.0℃ or ±0.75% |

|

N |

NiCrSi-NiSi |

Orange |

±1.5℃ or ±0.25% |

|

S |

PtRh10-Pt |

Black |

±1.5℃ or ±0.25% |

|

R |

PtRh13-Pt |

Pink |

±1.5℃ or ±0.25% |

|

B |

PtRh30-PtRh6 |

Gray |

±0.5% or ±0.5℃ |

In the above table, the thermocouple types include K, E, J, T, N, S, R, and B types, and each type has different alloy materials, insulation colors, and temperature error ranges. The temperature error range refers to the measurement error range of the thermocouple compensating wire within a certain temperature range, usually expressed in ±℃ or ±%. These parameters are very important for selecting the appropriate thermocouple compensating wire and can be selected according to actual needs.

5. Purpose

The thermocouple compensation cable is mainly used in the thermocouple measurement system, and its function is to compensate the potential change caused by the temperature change in the thermocouple measurement. Thermocouple compensation cables are widely used in metallurgy, chemical industry, electric power, petroleum, aerospace and other fields to measure temperature in high temperature, low temperature, corrosive media and other environments.

6. The difference between compensation cable and instrument cable

Compensation cables and instrumentation cables are both cables used in measurement systems, but their functions and structures are different. The compensation cable is mainly used in the thermocouple measurement system, and its function is to compensate the potential change caused by the temperature change in the thermocouple measurement. The structure of the compensation cable is usually a double-layer insulation structure, that is, the inner layer is a thermocouple wire, and the outer layer is a compensation wire.

Instrumentation cables are mainly used in measurement systems, and their role is to transmit signals or electrical energy. The structure of the instrument cable is usually a single-layer insulation structure, that is, the conductor and the insulation layer form a whole. The technical requirements of instrument cables usually include resistance, capacitance, insulation resistance, test voltage, etc., but compared with compensation cables, the requirements are usually more stringent.

K type Thermocouple cable KX/PVC/OSC/PVC is a cable specially used in the thermocouple measurement system, and its function is to compensate the potential change caused by the temperature change in the thermocouple measurement. The production standards of thermocouple compensation cables mainly refer to the IEC584 standard of the International Electrotechnical Commission (IEC) and the MC96.1 standard of the American National Standards Institute (ANSI). The structure of the thermocouple compensation cable is usually a double-layer insulation structure, and its technical characteristics include resistance, capacitance, insulation resistance, test voltage, etc. Thermocouple compensation cables are widely used in metallurgy, chemical industry, electric power, petroleum, aerospace and other fields to measure temperature in high temperature, low temperature, corrosive media and other environments. The technical requirements for instrumentation cables are generally more stringent than those for compensating cables.

Name: Lucky Li

Mobile:+86-18019826300

Tel:+86-0550-7788337

Whatsapp:+86-18019826300

Email:sales@chinajingzhou.com

Add:Jingsan Road, Xicheng District, Tianchang City, Anhui Province,China