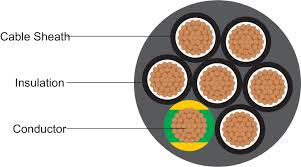

TRVV YSLY-JZ-600 flex control cable Structure

TRVV YSLY-JZ-600 flex control cable Features

Conductor cross-section

1.5 mm²

Conductor category

Cl.5 = finely stranded

Number of cores

5

Core insulation material

Polyvinyl chloride (PVC)

Core identification

Digits

Screen over stranding

Braid

jacket material

Polyvinyl chloride (PVC)

Coat Color

black

Flame retardant

according to IEC / EN 60332-1-2

Low smoke according to EN 61034-2

no

Outer diameter approx.

13 mm

Rated voltage U

1000V

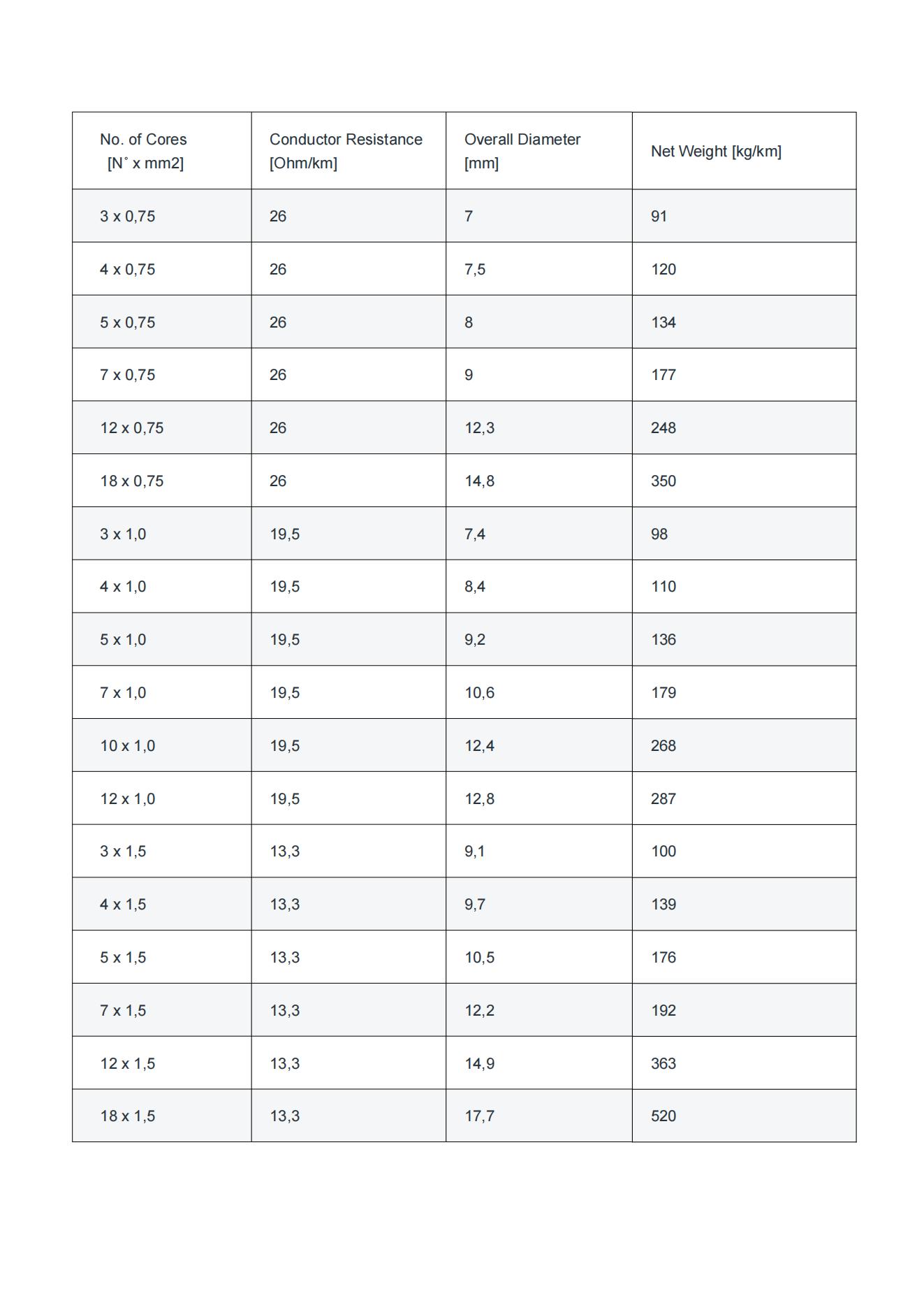

JZ-600 cables are available in a range of specifications to meet diverse application needs, with conductor sizes typically ranging from 0.5 mm² to 35 mm² and configurations from single-core to multi-core options.

Application Suitability: While both cables find their use in a broad spectrum of industrial applications, the YSLYCY-JZ's shielding feature renders it more appropriate for data.

TRVV YSLY-JZ-600 flex control cable represents a cornerstone in the realm of industrial cabling, offering a blend of flexibility, durability, and performance that meets the diverse demands of modern industrial applications. Its well-considered design ensures reliability in the most challenging conditions, making it a favored choice among professionals.

Comparatively, the YSLYCY-JZ cable adds a layer of EMI protection, extending its suitability to environments where electronic noise is a concern. Understanding the nuanced differences between these cables enables professionals to select the optimal solution for their specific needs, ensuring system integrity and performance.Name: Lucky Li

Mobile:+86-18019826300

Tel:+86-0550-7788337

Whatsapp:+86-18019826300

Email:sales@chinajingzhou.com

Add:Jingsan Road, Xicheng District, Tianchang City, Anhui Province,China