silicone rubber cable is divided into silicone rubber power cables, silicone rubber control cables, silicone rubber high-voltage cables, etc. It is suitable for mobile or fixed installation of electrical instrument connecting lines or signal transmission. The cable has good thermal stability and can maintain good electrical properties and flexibility in high temperature, low temperature and corrosive conditions. It is suitable for metallurgy, electric power, petrochemical and other industries. It is used in occasions with special requirements such as mobile temperature resistance.

Silicone rubber cable vs ordinary plastic cable:

Wires and cables play an important role in modern life, and silicone rubber cables have unique characteristics compared with ordinary cables. Here are the main differences between them:

Characteristics of silicone rubber cables:

Silicone rubber cable temperature resistance: Silicone rubber cable is suitable for use in the temperature range of -40-180°C. It has a lot of stability at high and low temperatures and has a longer life than ordinary cables.

The rubber coat is waterproof and wear-resistant: The outer coat of the silicone rubber cable is made of rubber, which has excellent waterproof and wear-resistant functions and is suitable for humid environments.

High cost: Due to its special properties, the price of silicone rubber cable is relatively high, which may limit its promotion and application in certain fields.

Anti-aging and wear-resistant: It has anti-aging, wear-resistant, oil-resistant, flame-retardant and other properties, and is suitable for some special environments and occasions.

silicone rubber control cable Basic model and name

|

KGG |

Silicone rubber insulation and sheath control cables |

|

KGGR |

Silicone rubber insulation and sheath control flexible cable |

|

KGGP |

Silicone rubber insulation and sheath copper wire braided shield control cables |

|

KGGRP |

Silicone rubber insulation and sheath copper wire braided shielding control flexible cable |

|

KGGRP1 |

Silicone rubber insulation and sheath tinized braided shield control flexible cables |

Basic cable specifications and structural parameters

|

Core * Nominal section (mm2) |

Conductor structure (Number of roots * diameter)mm |

Max. cable (mm) |

Reference weight (kg / km) |

||

|

|

|

KGGR |

KGGRP |

KGGR |

KGGRP |

|

2*0.75 |

24*0.20 |

9.2 |

10.0 |

78 |

118 |

|

2*1.0 |

32*0.20 |

9.5 |

10.6 |

87 |

127 |

|

2*1.5 |

48*0.20 |

10.2 |

11.5 |

114 |

164 |

|

2*2.5 |

51*0.25 |

10.5 |

12.5 |

156 |

210 |

|

3*0.75 |

24*0.20 |

10.5 |

11.5 |

93 |

133 |

|

3*1.0 |

32*0.20 |

11.5 |

12.9 |

100 |

152 |

|

3*1.5 |

48*0.20 |

12.0 |

13.8 |

126 |

177 |

|

3*2.5 |

51*0.25 |

12.5 |

14.8 |

180 |

243 |

|

4*0.75 |

24*0.20 |

11.0 |

12.5 |

110 |

160 |

|

4*1.0 |

32*0.20 |

11.5 |

13.0 |

120 |

173 |

|

4*1.5 |

48*0.20 |

12.0 |

13.5 |

151 |

205 |

|

4*2.5 |

51*0.25 |

14.5 |

15.5 |

220 |

270 |

|

5*0.75 |

24*0.20 |

12.0 |

13.0 |

118 |

168 |

|

5*1.0 |

32*0.20 |

12.5 |

13.5 |

140 |

200 |

|

5*1.5 |

48*0.20 |

13.0 |

14.2 |

190 |

250 |

|

5*2.5 |

51*0.25 |

14.0 |

15.2 |

290 |

380 |

|

model |

name |

|

YGCR |

Silicone rubber insulation and sheathed power cables |

|

YGCRP |

Silicone rubber insulation and sheath, copper strip shielded power cables |

1. Specifications and technical parameters

① Insulation thickness and spark test voltage

|

nominal cross |

2.5,4,6 |

10 |

16 |

25 |

35 |

50 |

70 |

95 |

120 |

150 |

185 |

|

insulation thickness |

1.0 |

1.2 |

1.4 |

1.6 |

1.8 |

2.0 |

2.2 |

||||

|

Spark breakdown voltage |

6000 |

7000 |

8000 |

9000 |

|||||||

② DC resistance of finished cable conductor core: the DC resistance of finished cable conductor core is the same as 0.6 / 1 kV PVC insulated electric cable.

③ Insulation resistance of finished cable core: the insulation resistance of finished cable insulation core, converted to the cable length of 1km and temperature of 20℃, the conductive wire core section of 50mm2 or below shall not be less than 50 MΩ, and 70-185mm2 shall not be less than 35 MΩ.

④ The finished voltage test of multi-core cable shall be subject to AC 50Hz, test voltage of 3500V and 5min.

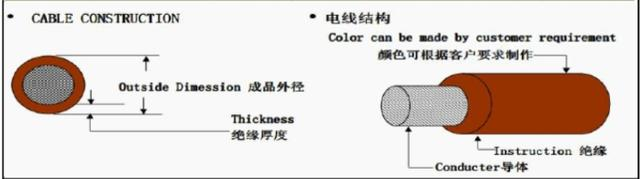

The structure of the electronic wire is basically composed of two parts, respectively, for the conductor and the insulation material. Therefore, the structure of the 3239 silicone wire is follows:

Conductor: single or stranded tin-plated copper wire.

Insulation material: silicone rubber.

High temperature resistance, low temperature resistance, fire resistance, wear resistance, corrosion resistance;

Excellent electrical insulation performance, excellent chemical stability energy;

High voltage resistance, aging resistance, long life, soft and easy to install.

Non-toxic, tasteless, harmless, soft, easy to bend and other characteristics.

Temperature range: -40℃ ~150 / 200℃, Rated temperature: 150°C

Rated voltage: 3KV / 6KV / 10KV / 20KV / 30KV / 50KV / 100KV / 200KV

Name: Lucky Li

Mobile:+86-18019826300

Tel:+86-0550-7788337

Whatsapp:+86-18019826300

Email:sales@chinajingzhou.com

Add:Jingsan Road, Xicheng District, Tianchang City, Anhui Province,China