BUS Cables A-BUS EPDM PUR 2X1.5 2X2.5mm2 are specifically designed for industrial networking and communication within automated environments. Each type of cable has unique properties tailored for specific applications and environments, ensuring reliability and performance. This article will detail the structure, characteristics, and uses of both A-BUS EPDM and A-BUS PUR cables, along with a comparative analysis to help professionals select the most suitable option for their needs.

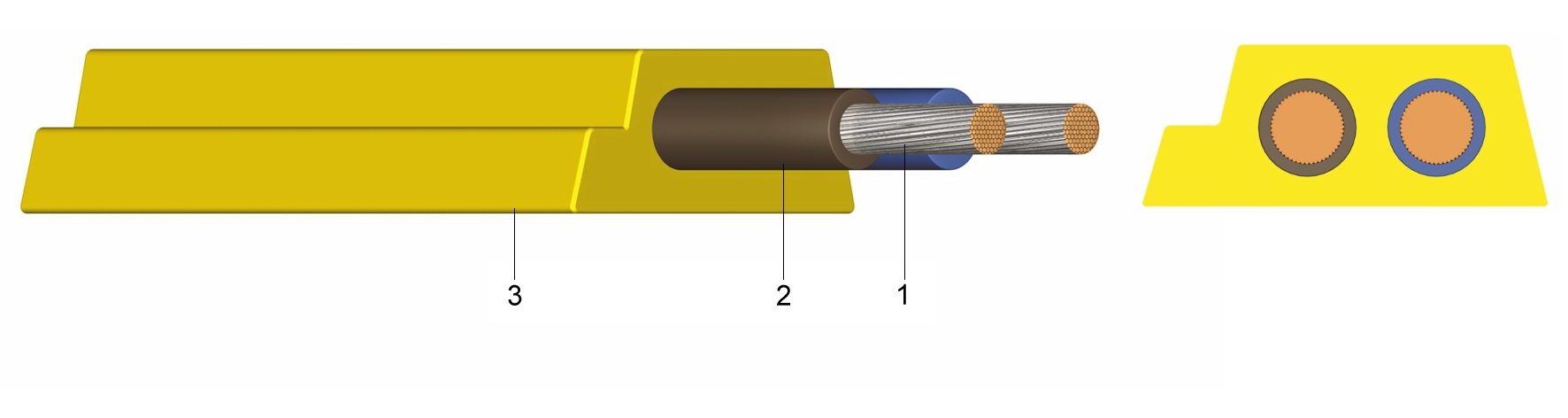

Conductor: BUS Cables A-BUS EPDM typically feature tinned copper conductors, which are highly conductive and resistant to oxidation, enhancing their longevity and performance in industrial applications.

Insulation: The insulation material used in A-BUS EPDM cables is Ethylene Propylene Diene Monomer (EPDM). EPDM is known for its excellent resistance to heat, cold, and chemical exposure, making it well-suited for harsh industrial environments.

Shielding: These cables may include a layer of aluminum mylar or tinned copper braid to shield against electromagnetic interference, crucial for maintaining signal integrity in environments with significant electrical noise.

Outer Jacket: The outer jacket is also made from EPDM, providing an additional layer of protection against physical and environmental stressors, such as UV light, oils, and abrasion.

Conductor: Similar to the EPDM version, A-BUS PUR cables use tinned copper conductors for excellent electrical performance and durability.

Insulation: Instead of EPDM, A-BUS PUR cables utilize Polyurethane (PUR) for insulation. PUR offers outstanding flexibility and abrasion resistance, which is beneficial for dynamic applications where cables are subject to frequent movement.

Shielding: A-BUS PUR cables also often include effective shielding mechanisms like those in the EPDM version, to protect against EMI and maintain reliable data transmission.

Outer Jacket: The outer jacket of PUR cables is made from Polyurethane, which is particularly noted for its excellent mechanical properties, including superior flexibility and resistance to cuts and tears.

Durability: Both types of cables are designed to withstand the rigors of industrial environments, but EPDM cables excel in extreme temperatures and chemical resistance, while PUR cables offer superior abrasion and mechanical stress resistance.

Flexibility: A-BUS PUR cables are generally more flexible than A-BUS EPDM cables, making them easier to install in tight spaces and around sharp bends.

Environmental Resistance: EPDM insulation is better suited for outdoor applications where cables are exposed to harsh weather conditions, whereas PUR is ideal for indoor industrial applications where physical wear is more of a concern.

EMI Protection: Both cable types provide excellent protection against electromagnetic interference, ensuring that data communication remains stable and reliable across various industrial scenarios.

A-BUS EPDM Cables:

A-BUS PUR Cables:

While both cables are robust and designed for industrial use, the choice between A-BUS EPDM and A-BUS PUR cables depends largely on the specific environmental conditions and mechanical requirements of the application:

1,Temperature and Chemical Resistance: A-BUS EPDM cables are preferable in extreme temperatures and environments with chemical exposure.

2,Flexibility and Mechanical Durability: A-BUS PUR cables are more flexible and durable against physical wear, making them ideal for indoor, dynamic environments.

Name: Lucky Li

Mobile:+86-18019826300

Tel:+86-0550-7788337

Whatsapp:+86-18019826300

Email:sales@chinajingzhou.com

Add:Jingsan Road, Xicheng District, Tianchang City, Anhui Province,China